Top 10 Largest Construction Equipment You Must See

Discover the top 10 largest construction equipment in the world that are revolutionizing the industry.

When it comes to the world of construction, size often matters. The largest construction equipment has revolutionized how massive infrastructure, mining, and excavation projects are carried out. From towering cranes to behemoth dump trucks, these machines not only impress with their size but also with their ability to tackle enormous tasks, ensuring projects are completed efficiently and effectively. Let's dive into the fascinating world of these giants.

Exploring the Giants: The Largest Construction Equipment

Each piece of equipment on our list is a marvel of engineering, designed to handle specific tasks that defy the limits of traditional machinery. Whether it’s mining for precious minerals or laying the groundwork for future cities, these machines play a pivotal role. They push boundaries, redefine scale, and prove that when it comes to construction, bigger often means better. Let's take a closer look at these titans that dominate the construction industry.

List of Top Choices

- 1. Bucket-Wheel Excavator

- 2. Dragline Excavator

- 3. Electric Rope Shovel

- 4. Crawler Tractor

- 5. Off-Highway Truck

- 6. Hydraulic Excavator

- 7. Crawler Crane

- 8. Tunnel Boring Machine (TBM)

- 9. Crawler Dozer

- 10. Motor Grader

1. Bucket-Wheel Excavator

- Key Feature: Extremely large wheel with numerous buckets designed to scoop material as the wheel turns.

- Application: Primarily used in open-pit mining for overburden removal and in large earthmoving operations.

- Notable Example: The Bagger 293, currently the largest in the world.

The bucket-wheel excavator (BWE) is a colossal machine that stands as a testament to human engineering prowess. This behemoth is primarily utilized in open-pit mining operations to remove overburden—the layer of soil and rock overlaying a mineral deposit—efficiently. The Bagger 293, recognized as the largest BWE, exemplifies the astonishing capabilities of these machines, featuring a wheel diameter that spans significantly, allowing it to move tens of thousands of cubic meters of material in a single day. Despite their massive size, BWEs are surprisingly efficient and can be operated with relatively low energy consumption, considering the volume of material they handle.

2. Dragline Excavator

- Key Feature: A large bucket suspended from a boom, operated through cables and pulleys.

- Application: Widely used for dredging in water bodies and deep pit mining.

- Notable Example: The Big Muskie was the largest dragline excavator ever built.

Dragline excavators, equipped with their distinctive large buckets hanging from a crane-like structure, play a crucial role in deep pit mining and dredging activities. The design allows them to dig deeply and remove large quantities of material from beneath the water's surface or in mining operations. The Big Muskie exemplified the peak of dragline capacity. While it no longer operates, its legacy underscores the vast potential of these machines to influence major excavation and mining projects. Draglines are particularly valued for their ability to excavate material that is beyond the reach of other types of excavators.

3. Electric Rope Shovel

- Key Feature: Powered by electricity, offering operational efficiency and reduced environmental impact.

- Application: Essential for loading extracted materials in open-pit mining operations.

- Notable Example: The P&H 4100XPC Electric Rope Shovel is among the most powerful and productive models.

Electric rope shovels are titans in the mining industry, renowned for their efficiency and reduced environmental footprint. These machines use electric motors to drive the movement of a massive digging bucket, making them more efficient and environmentally friendly compared to diesel-powered equipment. The P&H 4100XPC stands out in this category, offering unparalleled loading and digging capacity that significantly enhances productivity in open-pit mining operations. Its electrical drive system contributes to lower operating costs and reduced emissions, showcasing how modern advancements are shaping the future of large-scale excavation equipment.

4. Crawler Tractor

- Key Feature: Tracked design, providing exceptional ground holding capability and mobility over rough terrain.

- Application: Used for pushing large volumes of earth and for rough grading, often in conjunction with other earthmoving machinery.

- Notable Example: The Caterpillar D11, known for its robustness and efficiency in heavy-duty operations.

Crawler tractors, with their distinctive tracked design, are the workhorses of the construction and mining industries. The Caterpillar D11 represents the pinnacle of crawler tractor design, offering unmatched power and durability. These machines excel in moving vast amounts of soil and rock, making them indispensable for any major earthmoving project. Their tracked design enables them to navigate challenging terrains with ease, providing a level of versatility that wheeled vehicles simply cannot match. The D11, in particular, is celebrated for its reliability and efficiency, showcasing the critical role crawler tractors play in modern construction and excavation projects.

5. Off-Highway Truck

- Key Feature: Designed for heavy-duty loads, capable of operating in challenging off-road conditions.

- Application: Transporting large quantities of materials, such as dirt, rocks, and minerals, in mining and large-scale construction sites.

- Notable Example: The BelAZ 75710, holding the title for the largest haul truck in the world.

Off-highway trucks are the beasts of burden in the mining and construction sectors, built to carry immense loads across rugged terrains. The BelAZ 75710 stands as a giant among these titans, with the capability to haul an astonishing 450 metric tons of material. This makes it not only the largest but also one of the most powerful off-highway trucks in existence. Its design focuses on maximizing efficiency and reducing costs in large-scale operations, where moving materials quickly and safely is paramount. The BelAZ 75710's unmatched capacity demonstrates the scale of modern construction and mining projects, and the essential role of off-highway trucks in achieving operational success.

6. Hydraulic Excavator

- Key Feature: Highly versatile with a powerful hydraulic arm capable of digging, breaking, and lifting materials.

- Application: Commonly used in a wide range of construction projects, from small-scale building to large mining operations.

- Notable Example: The Komatsu PC8000-6, one of the largest hydraulic excavators in the world.

Hydraulic excavators, such as the Komatsu PC8000-6, embody versatility and power in the construction and mining industry. These machines are equipped with a hydraulic arm that can perform various tasks, including digging trenches, breaking hard materials, and lifting heavy objects. The strength of the hydraulic system allows for precise and efficient operation, making these excavators invaluable for projects of all sizes. The PC8000-6, with its significant size and strength, is particularly adept at handling the challenges of large-scale mining operations, demonstrating the crucial role hydraulic excavators play in modern construction and excavation practices.

7. Crawler Crane

- Key Feature: Mounted on crawler tracks, ensuring stability and mobility under heavy loads.

- Application: Ideal for lifting heavy items at construction and industrial sites.

- Notable Example: The Liebherr LR 13000, the world’s most powerful crawler crane.

The Liebherr LR 13000 represents the apex of crawler crane technology, combining immense lifting capacity with the stability and mobility provided by its crawler tracks. Capable of lifting thousands of tons, the LR 13000 is essential for constructing tall buildings, bridges, and installing heavy industrial equipment. Its design allows it to operate in various conditions, from tight urban spaces to rugged outdoor environments. This versatility, along with its unmatched power, underscores the vital role crawler cranes play in executing complex and heavy lifting tasks that define modern construction projects.

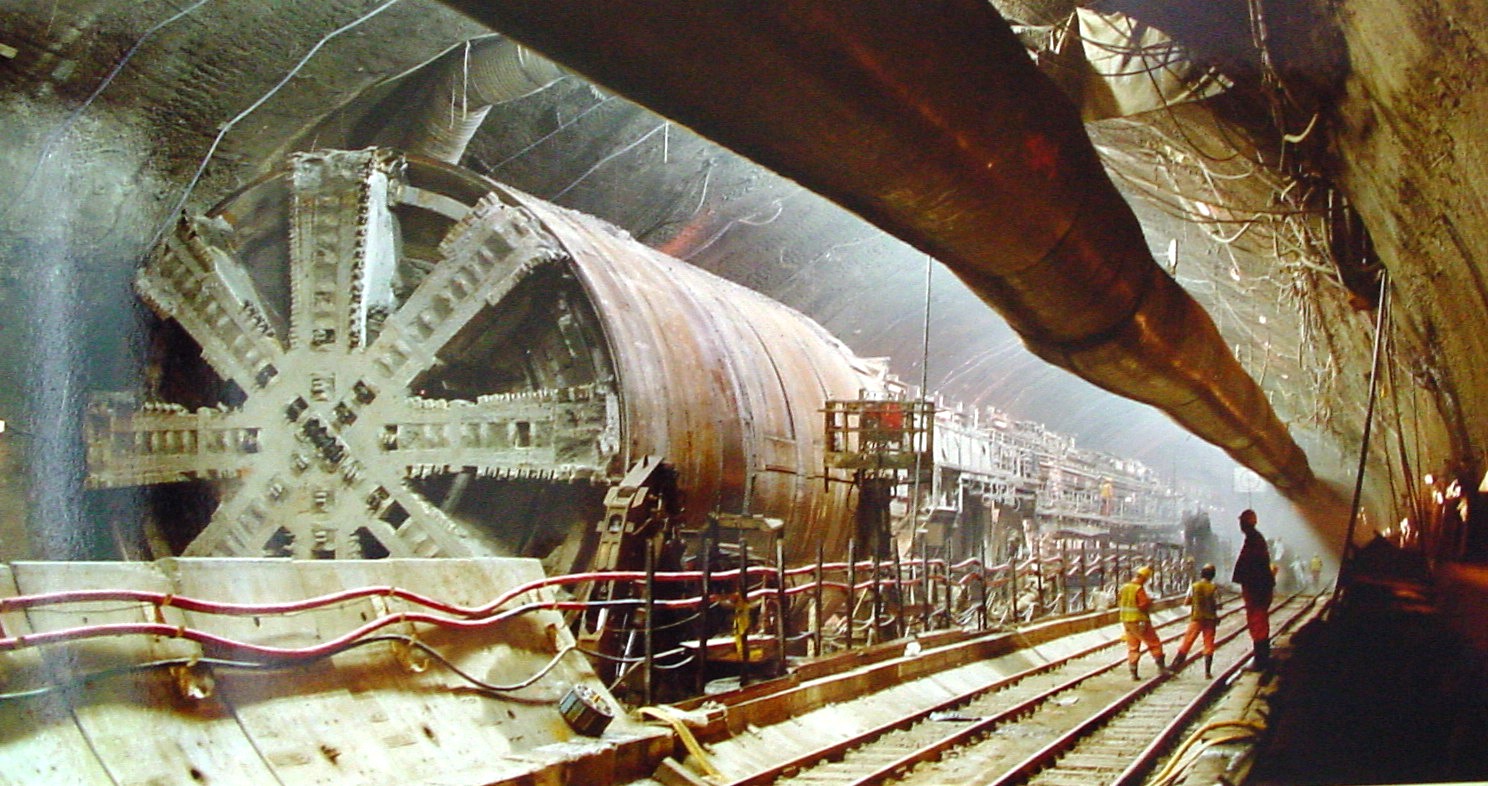

8. Tunnel Boring Machine (TBM)

- Key Feature: Specialized for efficient tunnel excavation, minimizing the need for disruptive ground excavation.

- Application: Used in constructing subways, railroads, and roadways where tunnels are required.

- Notable Example: The Bertha Tunnel Boring Machine, used in the Seattle Tunnel Project.

Tunnel Boring Machines (TBM), like the famous Bertha used in the Seattle Tunnel Project, are engineering marvels designed to bore through the earth with precision and efficiency. TBMs facilitate the construction of tunnels for various applications by minimizing the environmental impact and disruption typically associated with traditional tunneling methods. Equipped with cutting heads that can handle a range of geological conditions, TBMs such as Bertha illustrate the advancements in tunneling technology, enabling more ambitious and complex infrastructure projects to be realized. The role of TBMs in modern construction cannot be overstated, as they allow for the efficient and environmentally friendly creation of essential transportation and utility networks.

9. Crawler Dozer

- Key Feature: Robust tracked design equipped with a large blade for pushing large quantities of soil and rubble.

- Application: Essential for clearing and grading land, especially in construction and mining sites.

- Notable Example: The Komatsu D575A-3SD, the largest crawler dozer in production.

The Komatsu D575A-3SD stands as the king of crawler dozers, with an imposing presence and unmatched capability in moving soil, sand, and rubble. Its design revolves around its massive blade, which can clear and grade extensive areas of land with efficiency and precision. This capability ensures that the D575A-3SD is at the forefront of preparing sites for construction or mining operations, showcasing the importance of crawler dozers in the early stages of these projects. Their functionality makes them indispensable in the heavy equipment fleet, contributing significantly to the efficiency and speed of construction and mining operations.

10. Motor Grader

- Key Feature: Equipped with a long, adjustable blade used for creating flat surfaces.

- Application: Primarily used for road construction, grading, and snow plowing.

- Notable Example: The Caterpillar 24, renowned for its size and precision in grading operations.

Motor graders like the Caterpillar 24 play a crucial role in the construction and maintenance of roads. Their trademark long blade is adjustable for creating perfectly flat surfaces, which is essential for the foundational layers of roads and highways. The Caterpillar 24 exemplifies the balance between size for efficiency and precision control that modern motor graders achieve. This makes them uniquely capable of ensuring the roads we travel on are safe, level, and properly graded. In an industry where precision is as valuable as power, the motor grader stands out for its ability to finely tune landscapes, an essential last step in many construction projects.

In conclusion, the world of construction and mining is home to some of the most enormous and impressive machinery ever created. From the ground-breaking capacity of the bucket-wheel excavator to the precise grading capabilities of the motor grader, each piece of equipment plays a vital role in shaping our environment. Together, these top 10 largest construction machines exemplify the incredible achievements of engineering and technology, making possible projects that were once considered unimaginable. As we move forward, the continued innovation and evolution of these machines will undoubtedly drive the industry towards greater efficiency, safety, and sustainability, leaving us eager to see what giants the future will bring.

What's Your Reaction?